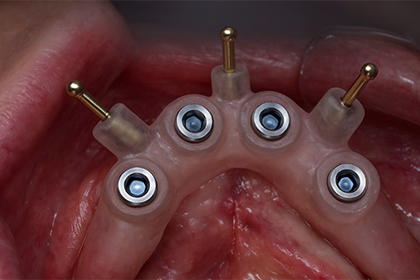

As dental technology advances, one of the most transformative tools in implantology is the 3D printed surgical guide. For trained dentists, this innovation represents a leap in precision, patient outcomes, and procedural efficiency. Custom-designed and patient-specific, these guides are revolutionizing implant placement by providing an accuracy level that was once unattainable.

1. Personalized Guides for Optimal Implant Placement

3D printed guides are customized to each patient’s anatomy, going far beyond traditional two-dimensional imaging and estimations.

How it works:

Using a CBCT scan and digital impressions, a 3D model is created to plan the ideal implant position. A guide is then printed to fit the patient’s mouth precisely, allowing controlled drilling at the exact depth, angulation, and position.

Case Study:

A patient with limited bone and a tilted molar benefited from a guide that avoided the inferior alveolar nerve, leading to precise placement and faster recovery.

Key takeaway:

Patient-specific guides significantly reduce surgical risks and ensure long-term success with fewer complications.

2. Reducing Surgical Time and Improving Efficiency

By preplanning implant placement, these guides help reduce chair time and increase procedural flow.

How it helps:

Once in place, the guide allows for immediate and accurate drilling, eliminating manual measurements during surgery.

Case Study:

In a full-arch restoration, multiple implants were placed using a single printed guide, reducing the procedure from 90 to 45 minutes.

Key takeaway:

3D guides make implant surgeries faster and smoother, improving productivity and patient comfort.

3. Minimizing Human Error and Enhancing Consistency

Even experienced surgeons can face visibility or angulation challenges. 3D printed guides minimize variability.

How it helps:

The guide locks the drill in place, ensuring every implant is placed as planned — consistently and safely.

Case Study:

For a full-arch implant case, multiple guides ensured predictable and repeatable results, leading to minimal discomfort and a smooth recovery.

Key takeaway:

Consistency in complex surgeries is achievable with printed guides, boosting reliability and outcomes.

4. Better Patient Experience and Outcomes

Patients expect implant procedures that are safe, fast, and effective — and guides deliver on all fronts.

How it helps:

Guides improve placement accuracy, leading to faster healing, fewer follow-ups, and better final aesthetics.

Case Study:

A patient with prior implant trauma received a same-day implant with a custom guide. Healing was swift, and the result exceeded expectations.

Key takeaway:

Accurate planning leads to better function, esthetics, and patient satisfaction — even in immediate-load cases.

5. Cost-Effective Long-Term Benefits

Though the initial tech investment may be higher, the efficiency and accuracy of 3D guides reduce overall clinical costs.

How it helps:

Fewer revisions, faster procedures, and higher retention rates improve profitability while enhancing care.

Key takeaway:

3D printing pays for itself through better outcomes, fewer complications, and practice growth.

Conclusion: The Future of Implant Surgery

3D printed surgical guides are redefining modern implantology. They:

- Increase precision

- Reduce surgical time

- Minimize error

- Enhance patient outcomes

By adopting this technology, you position your practice at the forefront of dentistry. Whether for a single implant or a full-arch restoration, 3D printed guides empower you to perform safer, faster, and more predictable surgeries.

Now is the time to integrate this technology and transform how you plan, place, and succeed with implants.