As dental technology continues to advance, one of the most transformative innovations in implantology has been the integration of Computer-Aided Design and Computer-Aided Manufacturing (CAD/CAM) systems. For trained dentists, CAD/CAM technology has revolutionized the way we approach dental implant procedures, offering faster, more precise, and highly customizable treatment options for patients.

In this blog, we’ll explore how CAD/CAM technology is enhancing modern dental implant procedures, improving outcomes, and transforming the patient experience.

1. Precision in Implant Planning and Design

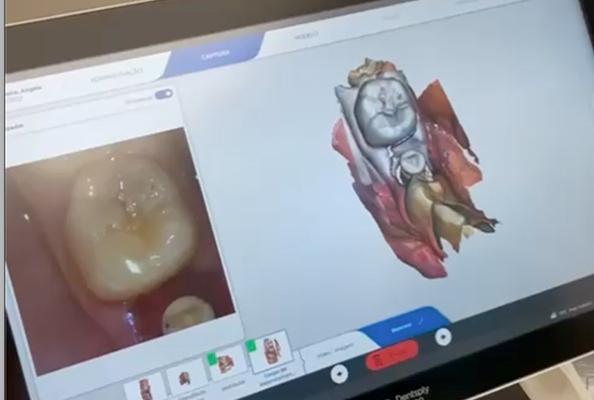

One of the primary advantages of CAD/CAM technology in dental implants is its ability to create highly accurate and personalized treatment plans. Traditional methods of implant planning often relied on 2D radiographs and manual measurements, which could introduce variability in the accuracy of implant placement. CAD/CAM systems, however, use 3D imaging (such as cone beam CT scans) to create detailed digital models of the patient’s anatomy, allowing for far more precise planning.

How it works:

With the help of digital scanning, a 3D model of the patient’s jaw is created, incorporating important anatomical landmarks, such as the bone volume, density, nerve positioning, and the proximity to vital structures like the sinuses. CAD software allows the dentist to design the ideal implant size, type, and position based on this 3D model, ensuring optimal placement for function, aesthetics, and long-term success.

Case Study: Precision in Complex Implant Placement

A patient presented with a severely resorbed maxillary ridge, making implant placement difficult using conventional methods. Using a CBCT scan and CAD software, we generated a highly accurate digital model of the patient’s jaw. This model allowed us to plan for bone grafting and the precise angulation of the implants. The result was a successful implant placement with excellent stability, reduced risk of complications, and no need for multiple revisions—thanks to the accuracy afforded by CAD/CAM.

Key Takeaway:

CAD/CAM technology allows for more accurate implant placement, ensuring optimal functionality and aesthetics while minimizing risks during surgery. This precision helps avoid complications like nerve damage or sinus perforation and reduces the need for adjustments or remakes.

2. Streamlining the Implant Workflow

CAD/CAM has significantly streamlined the implant workflow, from treatment planning to the final restoration. Traditionally, implant procedures involved multiple appointments and labor-intensive steps, including taking impressions, sending them to a dental lab, and waiting for restorations to be fabricated. With CAD/CAM, many of these steps can be done in-house and often in a fraction of the time.

How it helps:

Once the digital model of the patient’s mouth is created, the implant can be planned and designed virtually, reducing the time spent on manual tasks. The design is then sent directly to a milling unit, which creates the restoration (such as a crown, bridge, or full-arch prosthesis) with high precision. This process is faster, more efficient, and often results in fewer appointments for the patient.

Case Study: Immediate Restoration with CAD/CAM

A patient came in for an implant in the upper anterior region. Using CAD/CAM, we were able to plan the implant placement and design a temporary crown on the same day. The digital impressions and planning allowed us to create and place the crown in a single visit, reducing the time the patient had to spend without a functional tooth and improving their overall experience.

Key Takeaway:

CAD/CAM technology accelerates the entire process, reducing the need for multiple visits and shortening the time between implant placement and final restoration, improving the patient experience and practice efficiency.

3. Customization for Optimal Aesthetics and Function

Every patient’s mouth is unique, and CAD/CAM technology allows for a level of customization that traditional methods cannot match. With CAD/CAM, dentists can design restorations that are highly tailored to the patient’s individual anatomy, including tooth shape, color, size, and occlusion.

How it helps:

CAD software allows for precise design adjustments to ensure that implants and their restorations fit seamlessly with the patient’s natural dentition. This customization enhances both the functional and aesthetic outcomes of the treatment, ensuring that the implant not only performs well but looks natural and integrates smoothly with the surrounding teeth.

Case Study: Customized Full-Arch Restoration

A patient presented with extensive tooth loss in the lower arch. After placing the implants, we used CAD/CAM to design a full-arch restoration that fit the patient’s bite and aesthetic preferences perfectly. The software allowed us to adjust the design to match the natural contours of the gums and remaining teeth, resulting in a highly functional and lifelike prosthesis.

Key Takeaway:

CAD/CAM technology enables dentists to customize implants and restorations to meet the specific needs of the patient, resulting in better functional outcomes and more natural-looking restorations.

4. Reducing Human Error and Enhancing Consistency

Traditional methods of implant restoration, especially those involving multiple manual steps, are prone to human error. Variations in impressions, hand-made wax-ups, or manual measurements can all lead to inaccuracies in the final restoration. CAD/CAM systems, on the other hand, reduce the potential for human error by automating many aspects of the design and manufacturing process.

How it helps:

Because CAD software and milling machines operate based on highly accurate digital data, the resulting restorations are consistently precise. The same design specifications are replicated each time, ensuring that implants and their restorations fit as planned without the variability often seen with traditional methods.

Case Study: Consistent Results Across Multiple Implants

A patient required multiple implants in both the upper and lower jaws. Using CAD/CAM, we designed and fabricated the restorations for all the implants simultaneously, ensuring that each piece fit perfectly and was aligned with the rest of the dentition. This consistency was crucial for achieving optimal function, aesthetics, and patient satisfaction.

Key Takeaway:

CAD/CAM systems reduce the margin of error by relying on digital accuracy, ensuring consistent results with every restoration and improving the overall predictability of the implant procedure.

5. Improved Patient Experience and Satisfaction

In addition to the clinical benefits, CAD/CAM technology has a significant impact on the patient experience. With faster turnaround times, more precise restorations, and fewer appointments required, patients enjoy a smoother treatment journey. They also benefit from the natural-looking, highly functional results that CAD/CAM makes possible.

How it helps:

With CAD/CAM, patients experience fewer visits, less waiting time, and a higher degree of comfort throughout the process. The ability to create customized, aesthetic restorations also boosts patient satisfaction, as the final result looks and feels more natural.

Case Study: Faster Healing with CAD/CAM Restorations

A patient who underwent a single implant placement in the posterior mandible was able to receive a custom-designed crown within days of the procedure, thanks to CAD/CAM. The precise fit of the crown meant there were no adjustments required at the follow-up appointment, speeding up the healing process and minimizing the need for further intervention.

Key Takeaway:

With CAD/CAM, patients benefit from a quicker, more comfortable treatment experience, resulting in higher satisfaction and better outcomes.

Conclusion: CAD/CAM—A Game-Changer for Implantology

Incorporating CAD/CAM technology into your dental implant practice is no longer a luxury—it’s becoming a necessity in today’s competitive and patient-focused environment. From enhanced precision in treatment planning to faster, more efficient procedures and highly customized restorations, CAD/CAM is transforming the landscape of implantology.

For trained dentists, CAD/CAM systems offer the opportunity to improve clinical outcomes, streamline workflows, and enhance the overall patient experience. Whether you’re planning a single implant or a complex full-arch restoration, CAD/CAM technology provides the tools to ensure a precise, efficient, and aesthetically pleasing result.

Embracing CAD/CAM isn’t just about keeping up with the latest trends in dental technology—it’s about providing the best possible care to your patients and elevating your practice to new heights of success and efficiency. If you haven’t already integrated CAD/CAM into your practice, now is the time to explore how this cutting-edge technology can revolutionize your approach to dental implants.